Introduction:

With its accuracy and adaptability, resin 3D printers are capturing the attention of the design and fabrication industries. This manual will take you step-by-step through every aspect of resin 3D printing, revealing its fundamental principles, advantages, components, setup nuances, and safety considerations.

Resin 3D printers are a unique and effective instrument in the field of 3D printing. These printers produce elaborate, detailed prints that are challenging to produce using normal printing techniques because they need a special resin compound. We’ll delve deeply into the intriguing world of resin 3D printers in this article, covering everything from how they operate to how to set them up and keep them safe to use.

Understanding Resin 3D Printers:

Stereolithography (SLA) printers that use resin work differently from their filament-based counterparts in terms of how they work. They make use of a liquid resin that undergoes layer-by-layer curing utilizing UV light. They produce prints that are incredibly smooth and detailed, which makes them popular for uses like quick prototyping and jewelry creation.

The Electrosider team evaluated more than 10 resin 3D printers and selected the top 5 so that you wouldn’t encounter any issues.Here are the top 5 resin 3D printers, all of them are affordable and have fantastic features. You ought to unquestionably check it.

TOP 5 BEST RESIN 3D PRINTER

1.ELEGOO Resin 3D Printer, Mars 3 MSLA 3D Printer:( BEST OVERALL)

Because of its intriguing features and capabilities, the ELEGOO Mars 3 MSLA 3D Printer has attracted interest in the 3D printing community. This blog post will explore the benefits of the ELEGOO Mars 3, as well as some significant points prospective users should bear in mind.

Grab The Best Deal:

Check on AmazonUSER RATING: 4.6/5

Specifications:

- With fine features and smooth surfaces, ELEGOO Mars 3 is intended to produce prints of extraordinarily high quality. With the use of its MSLA (Masked Stereolithography Apparatus) technology, which uses an LCD screen to selectively cure resin, it is able to produce prints that are incredibly exact and precise.

- Even those new to 3D printing can use the Mars 3 because to its intuitive UI and touchscreen. From uploading models to changing parameters, the printing process is simplified by the easy controls.

- The dual matrix UV light source improves curing effectiveness, producing prints that are dependable and consistent. This method minimizes the possibility of uneven curing by ensuring uniform exposure throughout the build area.

- The ELEGOO Mars 3 supports larger prints thanks to a higher build space than its predecessors. For companies seeking to produce larger prototypes, models, or creative works, this is a considerable advantage.

Cons:

- The Mars 3 releases fumes during printing, much like all resin 3D printers do. For these vapors to evaporate and to avoid building up in the working area, there must be sufficient ventilation.

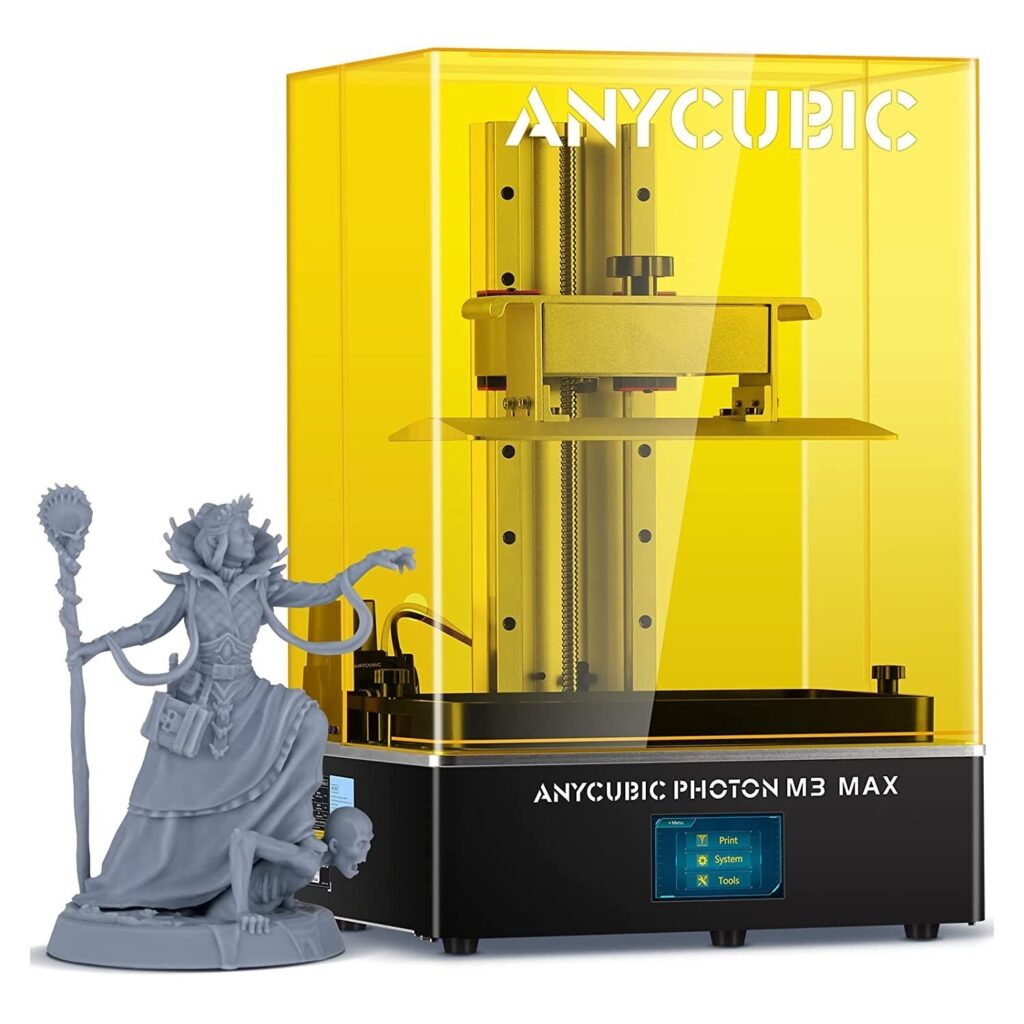

2.ANYCUBIC Resin 3D Printer, Photon M3 Max SLA LCD UV Resin Printer:

The ANYCUBIC Photon M3 Max Resin 3D Printer is a major competitor in the market as the field of 3D printing continues to develop. This printer has attracted interest from both pros and enthusiasts because to its feature set and promise of high-quality prints. If you want you should skip it because it is a high budget 3d printer. If you are a Enthusiasts and you have to work on one of these then you should definitely go for it.

Grab The Best Deal:

Check on AmazonUSER RATING: 4.4/5

Specifications:

- With its huge build capacity, the Photon M3 Max enables you to produce larger and more complex prints without the use of additional parts or assembly.

- The Photon M3 Max uses SLA (Stereolithography) technology to provide outstanding print quality with fine details and smooth surfaces. This qualifies it for the creation of fine jewelry, prototypes, and miniatures.

- The straightforward touchscreen interface makes printing easier. It offers simple access to file management, settings, and real-time print progress monitoring.

- The air filtration device that comes with the Photon M3 Max helps to reduce the emission of resin fumes during printing, improving workplace safety.

Cons:

- As of you know gys this a high budget resin 3d printer, so you have to think before buying it.

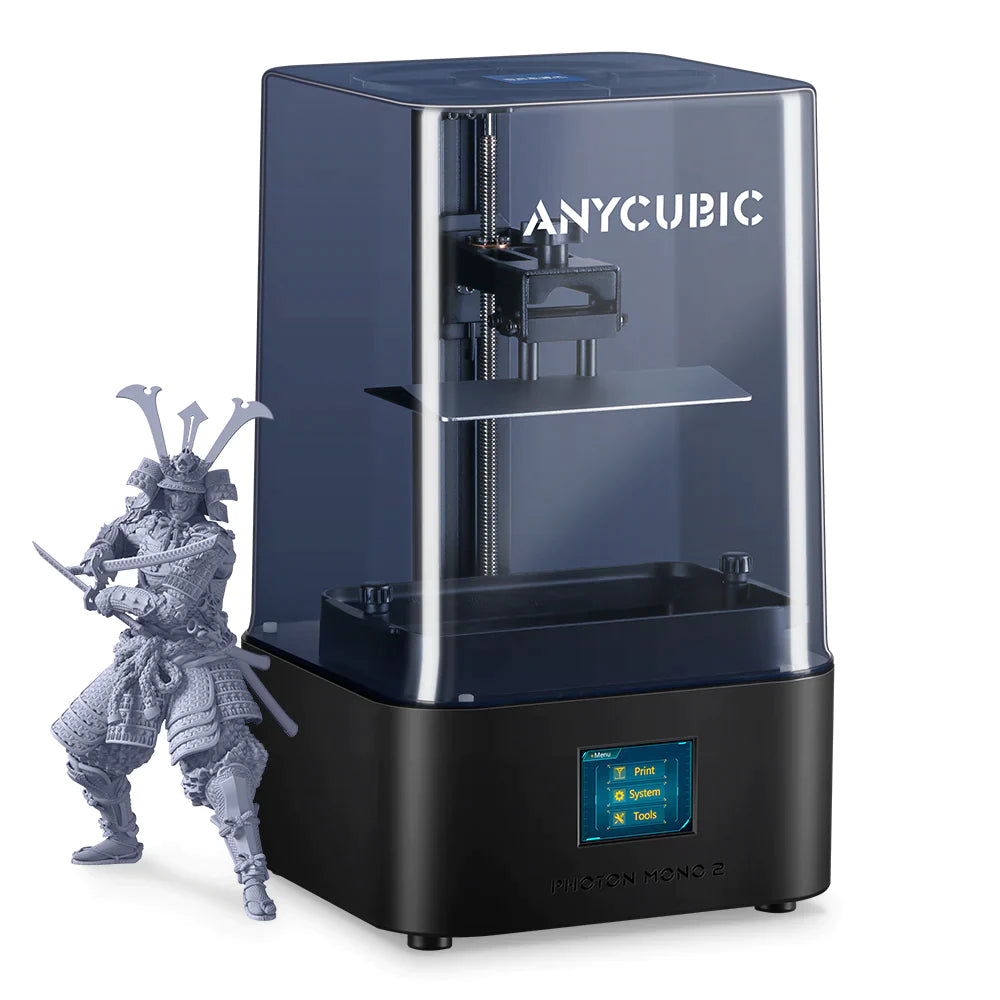

3.ANYCUBIC Photon Mono 2, Resin 3D Printer:( BEST IN THE BUDGET).

Due to its user-friendly features and guarantee of high-quality resin prints, the ANYCUBIC Photon Mono 2 has attracted interest in the world of 3D printing.

Grab The Best Deal:

Check on AmazonUSER RATING: 4.3/5

Specifications:

- The 6.6-inch monochrome LCD screen in the ANYCUBIC Photon Mono 2 has a resolution of 4096×2560 and can display the models’ minute details. This is a great option for switching from FDM printers to LCD printers because it can completely meet the printing needs of miniature models.

- The printer has a clever cooling mechanism that keeps the resin from being damaged by too much heat during printing. The curing procedure is improved by this cooling device, which also keeps print quality constant.

- Core capabilities like slicing, punching, support adding, shells extracting, and model layout have been improved and upgraded in Photon Workshop 3.0.

- The Photon Mono 2 is comparatively simple to set up and use, even for beginners. Slicing and printing objects is simple because to the touch screen interface and intuitive navigation, which lowers the learning curve involved in resin 3D printing.

Cons:

- The handling of potentially dangerous materials occurs during resin printing. To reduce dangers, users must take measures, put on safety gear, and use the printer in a well-ventilated location.

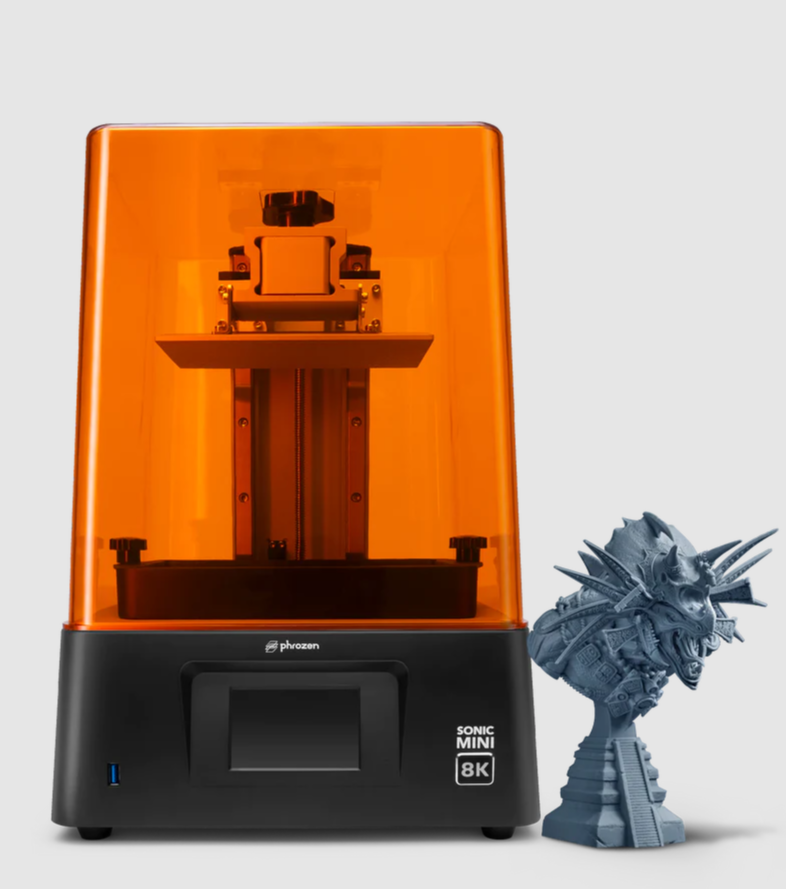

4.phrozen Sonic Mini 8K S LCD Resin 3D Printer:

Innovations like the Phrozen Sonic Mini 8K S LCD Resin 3D Printer are pushing the envelope of what is feasible in the realm of 3D printing.

Grab The Best Deal:

Check on AmazonUSER RATING: 4.2/5

Specifications:

- The Sonic Mini 8K S, as its name suggests, has a stunning 8K (3840 x 2400 pixels) LCD panel. This results in prints with exceptionally high resolution, fine details, and sharp edges.

- The Phrozen Sonic Mini 8K S delivers quality without sacrificing speed. In contrast to conventional color LCD screens, it uses monochrome LCD technology, which allows for quicker layer drying times.

- The Sonic Mini 8K S is a great option for both new and seasoned 3D printing fans who want to enhance their setup without going over budget due to its sophisticated capabilities but still reasonable price.

- Due to its small footprint, the Sonic Mini 8K S is appropriate for people with restricted workspace. It also has a slight visual appeal due to its contemporary design.

Cons:

- Working with resin can be messy and requires correct handling and cleanup, just like with any resin 3D printer. To reduce exposure to fumes, it’s critical to wear protective gear and work in a well-ventilated location.

5.Creality Resin 3D Printer Halot-Lite 8.9″ :

Part of Creality’s expanding lineup of resin 3D printers is the Halot-Lite 8.9″ model. With an 8.9-inch 2K monochrome LCD screen, it offers a quicker print time and a longer screen life.

Grab The Best Deal:

Check on AmazonUSER RATING: 4.1/5

Specifications:

- The Creality Halot-Lite Resin 3D Printer’s in-house developed integrated light source uses reflection and refraction to ensure a uniform distribution of light intensity over the entire screen.

- The Creality resin printer has an 8.9-inch monochrome LCD screen with a resolution of 4K HD (3840×2400), only requires 1-4/layer contact curing resin, and can print models with the highest level of detail while using less resin and less time.

- Creality Cloud APP for controlling printing parameters, monitoring print progress, and starting/stopping prints. Firmware updates can be made with one click thanks to built-in Wi-Fi.

- You can effortlessly handle the Halot-Lite 3D printer’s operation with its large touch screen, intuitive interaction, and straightforward visual interface.

Cons:

- Despite having a good build capacity, some users might find the Halot-Lite to be too small for larger project.

OUR CHOICE:

Our team chose and selected the top 1 from the above-mentioned top 5 best resin 3D printers for you guys.So we chose ELEGOO Mars 3, which uses the stereolithography (SLA) printing principles. Resin printers, as opposed to conventional filament-based printers, use a liquid resin that is layer by layer cured using ultraviolet (UV) radiation. The outcome? Smooth surface smoothness and fine details make these prints ideal for applications like quick prototyping and complex jewelry designs.

But if you doesn’t have that much budget, then don’t worry mates electrosider here for you. If tou have low budget then you should definitely go for the ANYCUBIC Photon Mono 2 that definitely a worthy oppent for ELEGOO Mars 3.

Benefits of Resin 3D Printing:

Resin 3D printing is superior than conventional filament-based 3D printing in a number of ways. These consist of:

- The exquisite features and flawless surface quality of resin prints are well known.

- For particular uses, speciality resins, flexible resins, and standard resins are all available.

- Resin printers are excellent at creating complex designs with few layer lines.

- Resin prints frequently offer faster total print times because to the shorter curing durations between each layer.

Step-by-Step Setup Guide for Resin 3D Printer:

However setting up a resin 3D printer may appear difficult, it is possible with accurate steps:

Select an Appropriate Workspace:

A well-ventilated, well-lit area should be chosen for your resin 3D printer. To disperse any potentially dangerous vapors that can be released during the printing process, adequate ventilation is crucial. To provide a secure environment, think about using an enclosure or installing a ventilation system.

Setting up the printer:

To put together your resin 3D printer, follow to the manufacturer’s instructions. The build platform must typically be attached, the printer bed must be leveled, and all parts must be firmly fastened. Spend some time making sure the alignment is correct because it has a direct impact on the print’s quality.

Make the resin ready:

Make sure the resin vat for the printer is clean and level before starting. Pick the resin that is best for your project and fill the vat with it to the suggested fill line. Avoid overfilling since it can result in untidy prints and interfere with the printing process.

Slice and Upload the Model:

To get your 3D model ready for printing, use slicing software appropriate for resin 3D printers. Making your 3D model into printable layers is known as “slicing.” According to the manufacturer’s guidelines and your particular needs, adjust settings including layer height, exposure time, and support structures.

Once the model has been cut into slices, save it in a file format that your printer can read and transfer it to a USB drive or another file input medium.

Balance the Build Platform:

To level the build platform, according to the printer’s instructions. This procedure helps to avoid printing failures by ensuring that the initial layer sticks adequately to the platform. While some printers have automatic leveling capabilities, some need manual adjusting. Better stickiness is ensured by proper leveling, which also lowers the possibility of print separation throughout the process.

Load the model, then begin printing:

Place your sliced model on the USB drive inside the printer. To find and choose your model, use the printer’s interface to navigate. Verify every parameter, including the layer height and print speed, before starting the printing process. Your 3D item will be gradually constructed by the printer as it starts the layer-by-layer curing process.

Maintain Your Printer:

The key to maintaining your resin 3D printer in top shape is routine maintenance. After each print, wash the resin vat, construction platform, and other parts. Check the printer for signs of wear and tear and carry out any required maintenance according to by the manufacturer’s instructions.

Safety Precautions When Using Resin 3D Printers:

To protect both your safety and the caliber of your prints when using resin 3D printers, you must take special care to follow safety precautions. Here are some crucial safety measures to take:

Protective Gear:

- To avoid coming into close touch with resin, which can irritate the skin, wear nitrile gloves.

- To shield your eyes from unintentional spills or odors, wear safety goggles.

Ventilation:

- To reduce exposure to fumes, operate the printer in a well-ventilated space.

- To direct fumes away from your work area, utilize a fume extractor or install a fan, if possible.

UV Protection:

- Avoid being directly exposed to UV light that is released during printing.

- To avoid UV leakage, make sure your printer is adequately enclosed.

Spill Prevention:

- To prevent resin spillage, put a disposable pad or tray under the printer.

- Any spills should be cleaned up right away using paper towels and isopropyl alcohol.

Storage & Clean Work Area:

- Store resin and printing supplies away from heat sources and in a cold, dark location.

- Keep your workspace tidy to avoid resin buildup on surfaces and equipment.

Problems with Resin 3D Printer & Their solution:

Resin 3D printers have amazing possibilities, but they also have their share of drawbacks. In this section, we’ll examine some of the major issues that users of resin printers could run across and provide workable answers to these challenges.

Print Failure from Sticking Problems:

Misprints or a resin slime can occur when prints don’t stick to the build platform.

Solution:

- For proper connection, make sure the build platform is leveled properly.

- To make prints stay, apply a small coating of adhesive, such as painter’s tape or specialized adhesion sheets.

- Keep the resin vat and construction platform clean on a regular basis to avoid debris from impairing adhesion.

Removable components and failed supports:

Prints might fail or develop disconnected portions due to insufficient or poorly planned supports.

Solution:

- Use slicing software to build reliable, strategically placed supports.

- For complex or large types, raise the supports’ volume and breadth.

- Make sure the model is set up to reduce the requirement for substantial supports.

Layer Shifts and Misprints:

Due to mechanical problems or motor imperfections, print layers may shift.

Solution:

- Check the tightness and functionality of the belts, screws, and other mechanical components.

- Make sure all moving parts are adequately lubricated to avoid problems brought on by friction.

- To prevent shifts caused by temperature, keep the ambient temperature steady.

Sticky Prints and Ineffective Curing:

Due to poor resin usage or inadequate curing, prints may continue to be sticky.

Solution:

- By modifying printer settings, make sure each layer has enough time to cure.

- Before usage, thoroughly mix the resin to achieve uniform outcomes.

- Prints that have been post-processed under UV light receive extra curing to remove stickiness.

Unclear or Cloudy Prints:

After curing, prints may still appear foggy or indistinct, which will impact the final finish.

Solution:

- For better print outcomes, choose a suitable resin of superior quality.

- To ensure clarity, give prints the recommended amount of time to sufficiently cure under UV light.

- After printing, thoroughly clean the print and rinse it with isopropyl alcohol to get rid of any extra resin.

Conclusion:

For innovators, from engineers to artists, resin 3D printers have opened up a world of possibilities. Other printing techniques fall short of their ability to make prints that are as accurate, detailed, and useful as theirs. You can master the craft of resin 3D printing and bring your imaginative concepts to life by comprehending its functioning principles, advantages, and suitable setup and safety procedures. THANK YOU.

DISCLAIMER:

The electrosider team writes on topics we believe you’ll find interesting. Due to our affiliate partnerships with Amazon, Electrosider receives a share of the revenue you spend there.

Are resin fumes harmful?

Some resins release fumes that could be dangerous to breathe in. The risk is reduced by using proper ventilation and wearing safety gear. Exposure can be further decreased by operating in a designated area or by using air purifiers.

What’s the post-processing procedure for resin prints?

After printing, the print should be cleaned in isopropyl alcohol to remove any extra resin before being cured in UV light to solidify the ink. The strength and durability of the print are improved by proper curing.

What’s the difference between resin and filament 3D printers?

UV light is used to cure liquid resin in resin printers, which results in prints with smooth, high-quality surfaces. With their greater selection of materials and simpler post-processing, filament printers discharge molten plastic to produce layer lines.

Can I use different resins with my printer?

Some printers are made to function best with a specific resin. Third-party resins can function, but they may need testing and tweaking to produce the best results.